Time to dissect a real life object and remake it in Rhino!! In this project I will be remaking an object that has parts that can be removed and put back together! For this the measurements will need to be incredibly accurate!

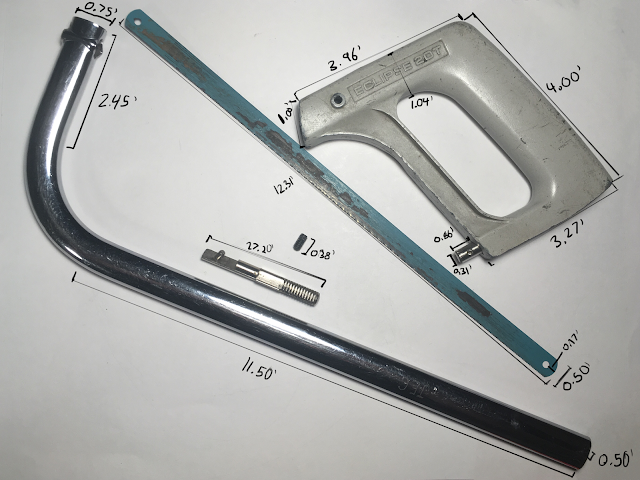

It took me some time to select an object that I could fully dissect. I decided to go with this hacksaw that my dad had in the garage because the curves on it will be challenging but interesting!

I did some basic measuring to lay down the groundwork! I will come back to add more details once I come to it.

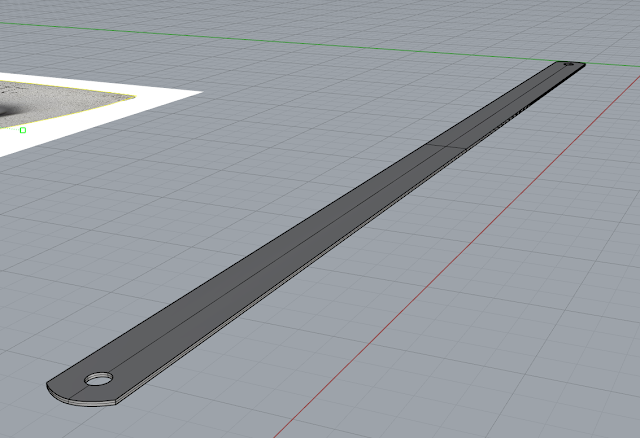

The blade itself has been the easiest part of this whole procedure.

The curves of the rest of the saw have been rather difficult to execute successfully. I managed to resize individual scans I took of the objects to get an accurate underlay I could use as a reference. I am still fixing them up but laying down the accurate measurements before rounding off corners and smaller details I'm finding is key.

I found setting it up to be the most difficult part, things did not want to line up, for awhile curves did not match with their proper measurements so I had to completely redo the lines I had made a few times. Might seem a little silly but I found scanning them the best way to get a flat side image of the objects. My hands were rather shaky otherwise with the camera and kept getting the wrong angles.

I found setting it up to be the most difficult part, things did not want to line up, for awhile curves did not match with their proper measurements so I had to completely redo the lines I had made a few times. Might seem a little silly but I found scanning them the best way to get a flat side image of the objects. My hands were rather shaky otherwise with the camera and kept getting the wrong angles.

No comments:

Post a Comment